Technologies

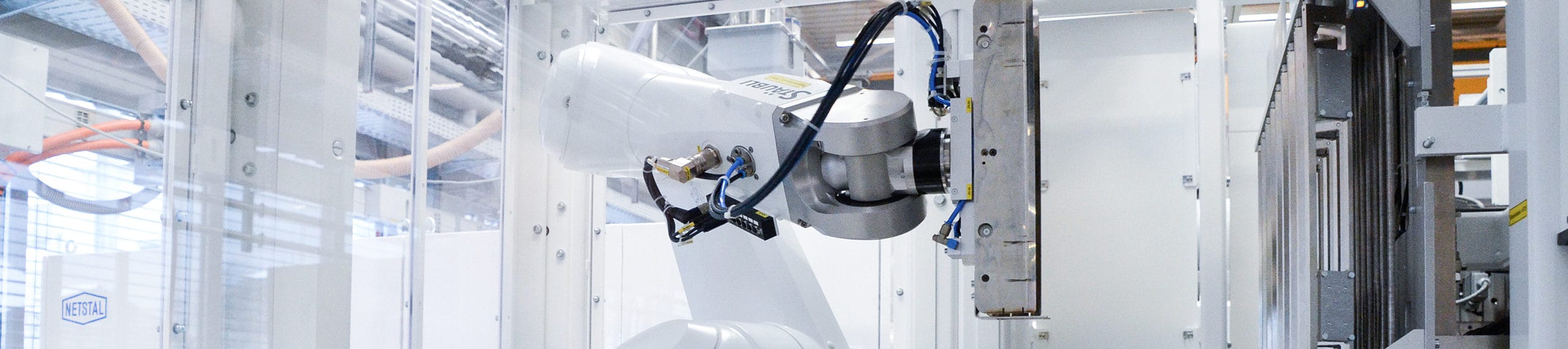

Reaching the target faster together

We know how to create optimal manufacturing concepts to meet product specifications, applying our knowledge of materials, tools, and automation. Get to your target faster and more efficiently with a custom-made solution. It's best to get us involved as early as possible.

Multi-component technologies

Close

Hybrid technologies

Close

Design technologies

Close

Future-oriented technologies

Close

Welding technologies

Close

Finishing technologies

Close

We are Kunststoff Schwanden

"Since my apprenticeship, I have been supported and promoted in my professional development. I enjoy solving technically demanding tasks."